HOW TO CHOOSE A CHEMICAL GLOVE?

When handling chemicals, it is important that workers’ hands are protected. When you start to choose the right chemical glove, it is advisable to ask the following questions:

– What type of chemicals will be handled?

– What type is the exposure to the chemical? Is it extensive or just splashes?

– What is the duration of exposure?

– Do you only need protection for your hands or do you also need protection for your arms?

– What grip is used?

Once the hazards have been identified, it is time to choose the right gloves. Chemical gloves can be made from a variety of rubber types – natural rubber, butyl, neoprene, nitrile and fluorocarbon (viton) – or plastics such as polyvinyl chloride, polyvinyl alcohol and polyethylene. These materials can be mixed or laminated for best results.

Basic materials for chemical gloves

Nitrile gloves are made of copolymer and protect against chlorine solutions (e.g. trichloroethylene and perchloroethylene). They provide protection when handling oils, fats, acids, alkalis and alcohols, but are generally not recommended for use with strong oxidising agents, aromatic solutions, ketones and acetates.

Neoprene gloves are made of synthetic rubber, which provides elasticity, good grip and tightness, and tear resistance. They protect against hydraulic fluids, petrol, alcohols and organic acids and alkalis. In general, they have better chemical and abrasion resistance than gloves made of natural rubber.

Gloves made of natural rubber (latex) are comfortable, offer excellent tensile strength, elasticity and temperature resistance. In addition to protecting against scratches from grinding and polishing, they also provide protection when working with acid, alkali, salt and ketone solutions. For those allergic to latex, alternatives such as hypoallergenic, lined or powder-free gloves are suitable.

Butyl gloves are made from synthetic rubber and protect against a wide range of chemicals such as peroxide, propellants, highly corrosive acids and strong alkalis. The gloves are oxidation and abrasion resistant and remain flexible even at low temperatures.

Standard EN 374

EN 374 describes the ability of gloves to protect the wearer from chemicals and/or micro-organisms.

EN 374-1 – The standard specifies general requirements for gloves that protect the wearer against chemicals and/or micro-organisms and defines the terms used.

EN 374-2 – Determination of resistance to penetration. This test includes air and water leakage tests. The glove must not allow water or air to pass through during the test. It also tests the compliance of gloves with the AQL (Acceptable Quality Level):

- Level 3 AQL must be 0,65

- Level 2 AQL must be 1,5

- Level 1 AQL must be 4,0

The AQL level indicates how many out of 100 gloves may be defective (i.e. the lower the AQL, the higher the quality of the product).

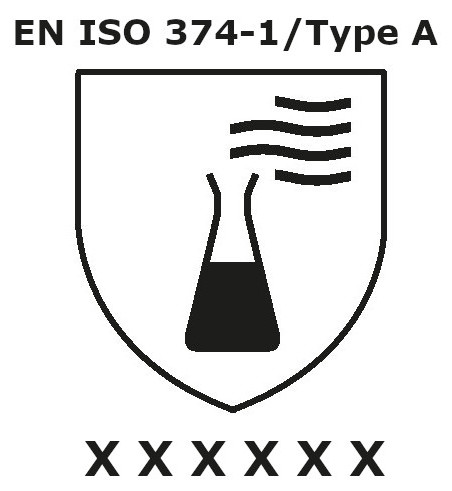

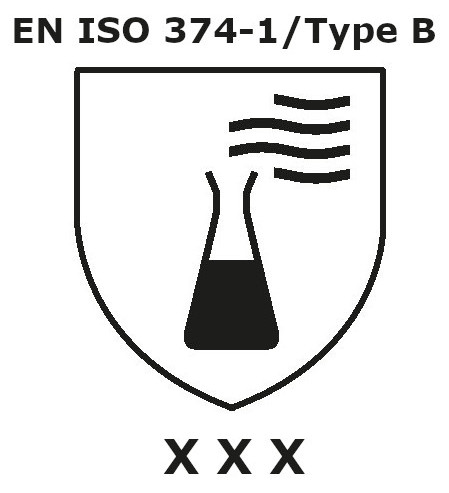

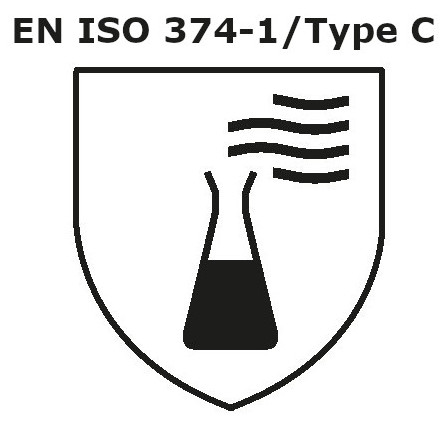

EN 374-3 has been replaced with EN 16523-1 – determination of resistance to permeation by chemicals. Test method for measuring the resistance of a material to chemical permeation. Gloves are classified into: Type A, Type B or Type C.

|  |  |

| Type A – for at least 6 listed chemicals, penetration time > 30 min | Type B – for at least 3 listed chemicals, penetration time > 30 min | Type C – for at least 1 listed chemical, penetration time > 10 min |

The alphanumeric codes associated with the chemical-resistant glove pictogram refer to the code letter of the chemical in the list of 18 standard chemicals with which the glove has been tested.

The list of chemicals for which gloves can be tested contains 18 names.

| Code Letters | Chemical | Cas No. | Class |

| A | Methanol | 67-56-1 | Primary Alcohol |

| B | Acetone | 67-64-1 | Ketone |

| C | Acetonitrile | 75-05-8 | Nitrile Compound |

| D | Dichloromethane | 75-09-2 | Chlorinated Hydrocarbon |

| E | Carbon Disulphide | 75-15-0 | Sulphur Containing Organic Compound |

| F | Toulene | 108-88-3 | Aromatic Hydrocarbon |

| G | Diethylamine | 109-89-7 | Amine |

| H | Tetrahydrofuran | 109-99-9 | Heterocyclic and Ether Compound |

| I | Ethyl Acetate | 141-78-6 | Ester |

| J | n-Heptane | 142-85-5 | Saturated Hydrocarbon |

| K | Sodium Hydroxide 40% | 1310-73-2 | Inorganic Base |

| L | Sulphuric Acid 96% | 7664-93-9 | Inorganic Mineral Acid |

| M | Nitric Acid 65% | 7697-37-2 | Inorganic Mineral Acid |

| N | Acetic Acid 99% | 64-19-7 | Organic Acid |

| O | Ammonium Hydroxide 25% | 1336-21-6 | Organic Base |

| P | Hydrogen Peroxide 33% | 7722-84-1 | Peroxide |

| S | Hydrofluoric Acid 40% | 7664-39-3 | Inorganic Mineral Acid |

| T | Formaldehyde 37% | 50-00-0 | Aldehyde |

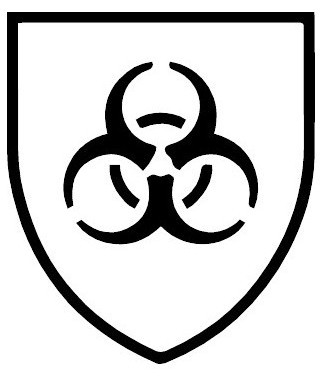

EN 374-5 – Protection against micro-organisms. Gloves with this pictogram protect against bacteria and fungi. If the pictogram is also accompanied by the word “VIRUS”, protection against viruses is also added.

SHOWA ChemRest®

There is more than 60 million chemicals (and the number is growing). Choosing the right chemical glove can be difficult. You need to understand what type of chemicals will be handled, how they are being used and what is the duration of exposure.

SHOWA ChemRest® is a chemical search engine – a platform where workers could check whether their gloves were really protecting them against the chemicals that they work with. Try ChemRest® HERE. After finding your suitable chemical glove on ChemRest.com contact us or ask for an offer becky@becky.ee. All the chemical gloves that are in stock and ready to be sent out can be found HERE.

Maintenance of gloves in a chemical environment

• Wash and dry hands thoroughly before handling gloves.

• For prolonged use, do not wear gloves for longer than recommended.

• Regularly check that the gloves have not become porous or show signs of wear.

• Wherever possible, wrap the sleeve over the gloves to avoid the substance contact with the arms.

• Follow the instructions in the manual before removing the gloves.

• When removing the second glove, do not touch the top of the glove, but slide your fingers from the wrist into the glove and then pull the glove off.

• Before using the gloves again, check that both gloves are dry inside and show no signs of wear.

Follow us on social media:

Join our mailing list! Sign up to receive email updates on new products, special offers and more.